United States, 19th Aug 2025, – Yijin Hardware, a precision manufacturing company specializing in CNC machining, sheet metal fabrication, and custom fasteners, with in-house capabilities in design, prototyping, production, and quality assurance, serving industries including automotive, aerospace, medical, and energy, has commissioned a new production line for turbo molecular pumps at its existing facility in Yabian Community, Shajing Street, Baoan District, Shenzhen, China. The initiative supports the growing global demand for high-vacuum system components across semiconductor manufacturing, research laboratories, and advanced manufacturing sectors.

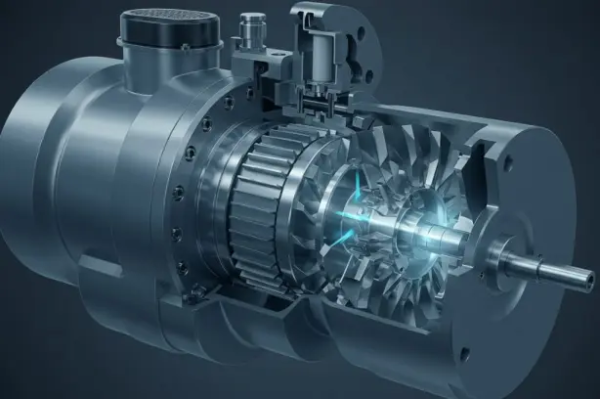

The turbo molecular pump production line has been configured to integrate high-precision rotor fabrication, advanced balancing systems, and stringent quality testing to ensure optimal performance in applications requiring ultra-high vacuum conditions. This commissioning follows an extensive planning phase, including equipment acquisition, workforce training, and process validation to meet international standards.

Turbo molecular pumps play a critical role in maintaining contamination-free environments in sectors such as semiconductor wafer fabrication, surface science research, and thin-film deposition. The Shenzhen-based production is designed to deliver both standard and customized pump configurations to accommodate varying throughput and integration requirements.

Gavin Yi, CEO of Yijin Hardware, commented on the new development, “The commissioning of turbo molecular pump production in Shenzhen represents a targeted expansion into precision vacuum technology manufacturing. This step leverages existing engineering capabilities while introducing specialized processes that meet the demanding performance requirements of high-vacuum system applications. The facility was structured to align with the operational expectations of industries where reliability and precision are paramount.”

The new line incorporates precision balancing and assembly procedures, alongside testing protocols that include vibration analysis, helium leak detection, and rotational speed verification. Each pump undergoes operational simulation to confirm sustained performance under target vacuum levels. The production capability also supports rapid prototyping, allowing engineering teams to adapt designs to evolving client specifications.

Location selection for the production line was influenced by Shenzhen’s established advanced manufacturing infrastructure, supply chain network, and access to specialized materials. The integration of the pump production within Yijin Hardware’s existing operations enables shared resources in machining, quality assurance, and logistics, thereby optimizing production flow and delivery timelines.

The introduction of this capability aligns with the increasing need for localized manufacturing of complex vacuum components, reducing dependence on extended global supply chains. This approach offers clients improved lead times and a more resilient procurement framework.

Industries relying on high-vacuum systems often face challenges in sourcing components that maintain performance consistency under demanding operational conditions. By integrating turbo molecular pump manufacturing into its portfolio, Yijin Hardware contributes to addressing these challenges through controlled production processes and adherence to rigorous testing standards.

Looking ahead, Gavin Yi stated, “The addition of turbo molecular pump manufacturing marks a significant step toward diversifying into specialized engineering sectors. Future developments will focus on enhancing pump efficiency, reducing operational noise, and integrating digital monitoring capabilities to support predictive maintenance. Continued investment in process optimization and collaborative engineering will ensure readiness to meet the requirements of emerging high-vacuum technologies.”

The Shenzhen production line is operational and ready to fulfill orders for clients in Asia, Europe, and North America. Initial production runs have already been scheduled, with delivery timelines coordinated to match project-specific requirements.

For inquiries regarding China turbo molecular pump factory, Yijin Hardware, headquartered at 760 NW 10th Ave, Homestead, FL 33030, USA, may be contacted at +1 626 263 5841 or yijing@yijinsolution.com.

Media Contact

Organization: Yijin Hardware

Contact

Person: Gavin Yi

Website:

http://yijinsolution.com/

Email:

yijing@yijinsolution.com

Address:760 NW 10th Ave

Address 2: Homestead, FL 33030

Country:United States

The post

Yijin Hardware Commissions Turbo Molecular Pump Production for High-Vacuum Systems in China appeared first on

Brand News 24.

It is provided by a third-party content

provider. Brand News 24 makes no

warranties or representations in connection with it.

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Citizen Wave journalist was involved in the writing and production of this article.